|

| November 17, 2015 | Volume 11 Issue 43 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wings:

3D-printed jet-powered UAV unveiled at Dubai Airshow

Aurora Flight Sciences' high-speed UAV is 80% 3D printed with Stratasys additive manufacturing solutions.

3D-printing and additive manufacturing solutions heavyweight Stratasys has teamed with Aurora Flight Sciences to deliver what is believed to be the largest, fastest, and most complex 3D-printed unmanned aerial vehicle (UAV) ever produced.

Unveiled for the first time at the Dubai Airshow last week, the high-speed aircraft was built using lightweight Stratasys materials to achieve speeds in excess of 150 mph.

To realize the joint goal to design and develop an advanced 3D-printed demonstration aircraft, the final UAV -- which has a 3-m (9-ft) wingspan and weighs only 15 kg (33 lb) -- leveraged 3D printing for 80% of its design and manufacture and is built on the expertise of Aurora Flight Sciences' aerospace know-how and Stratasys' additive manufacturing experience.

According to Dan Campbell, Aerospace Research Engineer at Aurora Flight Sciences, the project achieved various targets. "A primary goal for us was to show the aerospace industry just how quickly you can go from designing to building to flying a 3D-printed jet-powered aircraft. To the best of our knowledge, this is the largest, fastest, and most complex 3D-printed UAV ever produced."

"[The project] meant using different 3D-printing materials and technologies together on one aircraft to maximize the benefits of additive manufacturing and to 3D print both lightweight and capable structural components," says Scott Sevcik, Aerospace & Defense Senior Business Development Manager, Vertical Solutions at Stratasys.

According to Dan Campbell (pictured) from Aurora Flight Sciences, the new UAV is believed to be the largest, fastest, and most complex 3D-printed aircraft ever produced.

For Aurora, Stratasys' additive manufacturing solutions provided the design optimization to produce a stiff, lightweight structure without the common restrictions of traditional manufacturing methods. This also enabled the cost-effective development of a customized -- or mission-specific vehicle -- without the cost constraints of low-volume production.

Design and build time cut by 50% with Stratasys 3D-printing solutions

"Stratasys 3D-printing technology easily supports rapid design iterations that led to a dramatically shortened timeline from the initial concept to the first successful flight," says Campbell. "Overall, the technology saw us cut the design and build time of the aircraft by 50%."

A Stratasys rep says that the metal and nylon parts were produced at Stratasys Direct Manufacturing in Valencia, CA. All the FDM components were printed in Eden Prairie, MN. Final assembly also took place in Eden Prairie.

The longest print time was for the center body (fuselage), which took a little more than a week to build. 3D-print times included:

- Fuselage (FDM), 9 days

- Wings (FDM), 4 days

- Nozzle (DMLS), 5 days

- Fuel Tank (LS), 5 days

- Other small parts (FDM), ranging from a few hours to a day.

In all, a little more than a month was spent on the initial integration and assembly. If a second UAV was to be built, with all the integration worked through, it would take two to three weeks from start to finish.

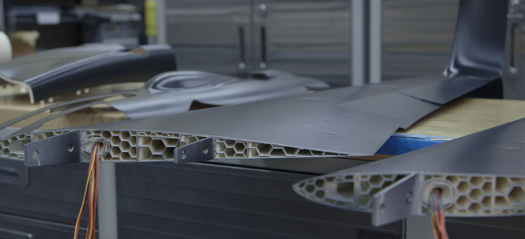

Aurora's UAV demonstrates the Stratasys FDM-based 3D-printing solution's ability to build a completely enclosed, hollow structure.

According to Sevcik, the project exemplifies the power of Stratasys' flagship Fused Deposition Modeling (FDM) 3D-printing technology.

"Aurora's UAV is a clear evidence of FDM's ability to build a completely enclosed, hollow structure which, unlike other manufacturing methods, allows large -- yet less dense -- objects to be produced," he explains.

"In addition to leveraging FDM materials for all large and structural elements, we utilized the diverse production capability of Stratasys Direct Manufacturing to produce components better suited to other technologies. We elected to laser-sinter the nylon fuel tank, and our thrust vectoring exhaust nozzle was 3D printed in metal to withstand the extreme heat at the engine nozzle," Sevcik says.

"Because Stratasys is able to produce parts that meet the flame, smoke, and toxicity requirements set by the FAA, ULTEM has become the 3D-printing material of choice for many of our aerospace customers for final production applications," he says.

For Sevcik, this particular collaborative project with Aurora achieves one of the foremost overall goals among aerospace manufacturers, as well as those in other industries, which is the need to constantly reduce weight.

"Whether by air, water, or on land, lightweight vehicles use less fuel. This enables companies to lower operational costs, as well as reduce environmental impact," he says. "In addition, using only the exact material needed for production is expected to reduce acquisition cost by eliminating waste and reducing scrap and recycling costs."

Source: Stratasys

Published November 2015

Rate this article

View our terms of use and privacy policy